INDUSTRIAL VALVES PN40 – PN630 for CO2 or H2

We would like to introduce you hereby other possible solutions that we have implemented for our clients during the year 2021. These are products from the field of industrial valves designed as a control unit, which also holds and performs the function of a closing element in the required tightness classes defined by the customer.

We deliberately chose an application for the presentation, where the media flowing through the fittings are a gas such as hydrogen – H2 or liquid carbon dioxide – C02, in order to declare the closing function even for such demanding parameters.

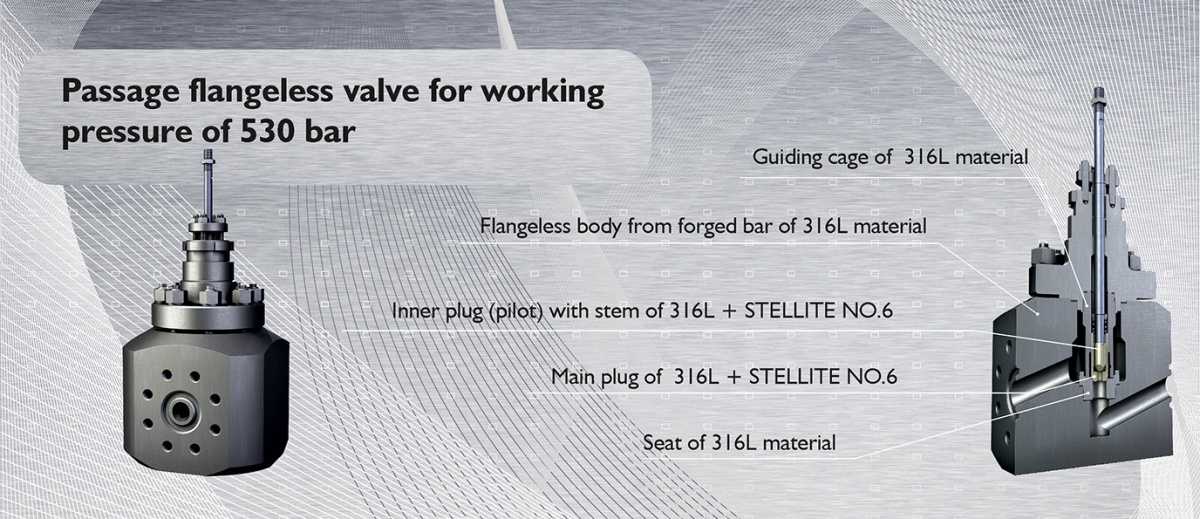

Application for liquid carbon dioxide – CO2

All parts of the presented valve are made of 316L steel and the counter flanges are made of X2CrNiMoN22-5-3 1.4462 (DUPLEX).

Due to the working pressures of up to 530 bar, the valves were manufactured for a nominal pressure of PN630 according to the BN-91 1771-20 / 40 standard. A BX 150 gasket according to API 6A 15000 psi is designed between the valve body and counter flanges.

The valves have a guaranteed tightness class V according to ANSI FCI 70-2 between the plug / seat at a full pressure drop of 530 bar and the medium flow above the plug (FTC).

The pressure difference above and below the plug during closing causes additional pressure and seals the system. In order to reduce the required disposition force of the actuator, the construction of a pressure-balanced plug with an inner plug, was used. The pilot plug was chosen so that the force needed to open it was 7 times less than the main plug. After opening the pilot plug, the pressures above and below the main plug equalize and further opening does not require more actuator force to achieve full stroke.

To prevent wear down of the internal parts caused by the very high flow rate of the liquid carbon dioxide – CO2, the internal parts and guiding sleeve are made of a fully stellite coating with a hardness of 45 HRC.

The valves are equipped with pneumatic actuators controlled by 3/2 way solenoid valves or digital positioners with the possibility of equipping with limit switches or a 4/20 mA position transmitter.

Hydrogen gas application – H2

Figure 2 shows one of the other solutions manufactured by VALVEA for the ORLEN Group, namely control valves with class V shut-off function according to ANSI FCI 70-2 intended for Zone 2, group IIC with a special customer design and the following connection variants DN120 PN350, DN90 PN350, DN58 PN350, DN45 PN350.

Required parameters:

• Medium: gas mixture H2-63%, N2-22%, NH3-4%, CH4-9%, Ar-2%

• Maximum temperature: + 450C

• Maximum pressure: 280 bar